Services

Machine shop facility

We use cutting-edge production equipment for the flexible manufacturing of either one-off products (molds) or small batches. Our infrastructure and expertise enable us to handle pieces of large dimensions, up to 1200x510x560 mm. The highly skilled and experienced personnel working in our CNC milling and turning centers ensure optimum precision at the fastest lead times.

We carry out all the necessary coordination with outside suppliers for heat treatment, anodizing, painting, silver-plated, gold-plated.

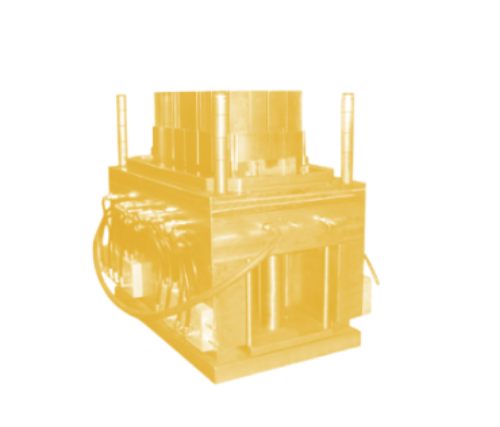

Assembly and Maintenance

We consider mold manufacturing an art and use high-tech computer numerical control (CNC) machines to ensure absolute precision. That said, the human factor continues being integral in our processes, yet in a more supervisory role.

In addition to assembly, we also offer maintenance services and spare parts manufacturing of sub-assemblies. Molds produced by Sunlight Technosystems are vigorously tested in our facilities so that the final product meets all customer requirements.

Thermoplastics Production Unit

We mold plastic pieces up to 4 kg in our state-of-the-art facilities in Kilkis, Central Macedonia, and Xanthi, Eastern Macedonia-Thrace, carrying extensive experience from years of handling a wide range of thermoplastic materials, such as: PP, ABS, PA, PE, NORYL etc. We also process polysulfone (PSU), mixtures of different colors and materials – including flame-retardants, glass-fiber reinforced etc.

Our competitive advantage stems from the in-house management of the entire production process of plastic components in our facilities: from the design, to manufacturing and maintenance, to the delivery of the final product to the premises of our customers. This saves time and resources, while also promoting circular economy and sustainability.

Quality Control & Management

We deliver the final product to our customers only after verifying it meets all their requirements to their satisfaction.

To that effect, we perform quality checks using 3D probes, optical projectors, electronic calipers, as well as statistical process techniques. The company also uses the CMM machine for counting the produced goods. The machine provides the ability for: 1. Loyalty, fast and easy counter of the whole width of the geometricals and dimensionals tolerances. 2. Scanner-copy and print in enviroment CAD or/and check and comparison of the surfaces and parts geometry. Sunlight Technosystems is certified to the ISO 9001:2015, 14001:2015 and 45001:2018 standards by TUV Hellas.